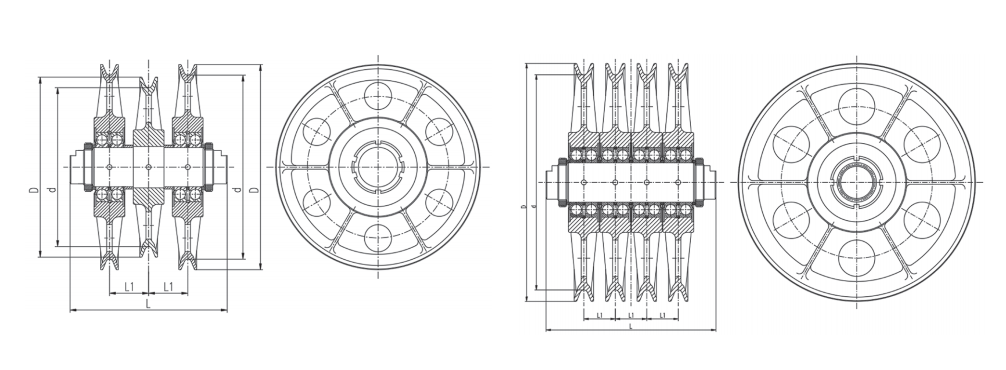

1.Load Distribution: A Crane Pulley spreads the lifting force across several ropes, which reduces strain on each rope.

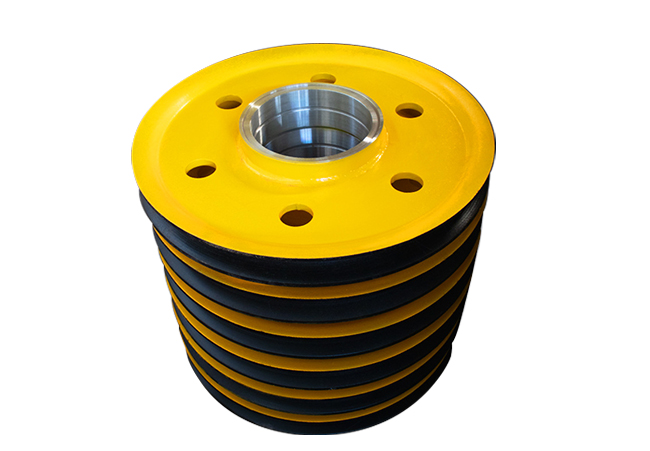

2.Durability: Each crane pulley block is made from alloy steel and produced with precision machining.

3.Smooth Operation: The groove of the crane pulley wheel is hardened to reduce rope wear and keep lifting stable.

Crane Pulley systems are essential parts of lifting machinery. They protect ropes, reduce effort, and keep lifting operations reliable in overhead, gantry, and tower cranes.