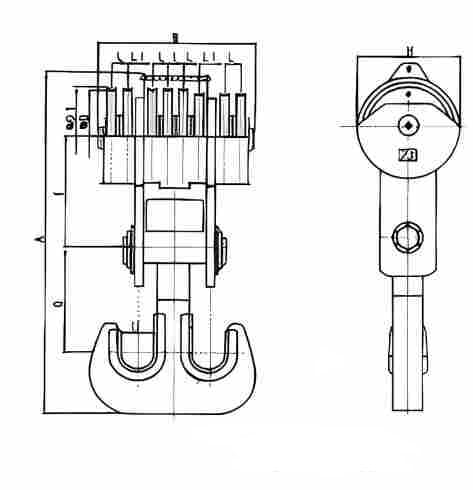

The crane double hook block is forged from high-strength alloy steel and treated for maximum durability. Its dual-hook design distributes loads evenly, minimizing swing and enhancing lifting safety. Each hook block crane is tested with ultrasonic inspection and overload verification to guarantee long service life. Customization is available for different crane hook block types and crane hook block weight, making it suitable for standard, port, and mobile cranes.