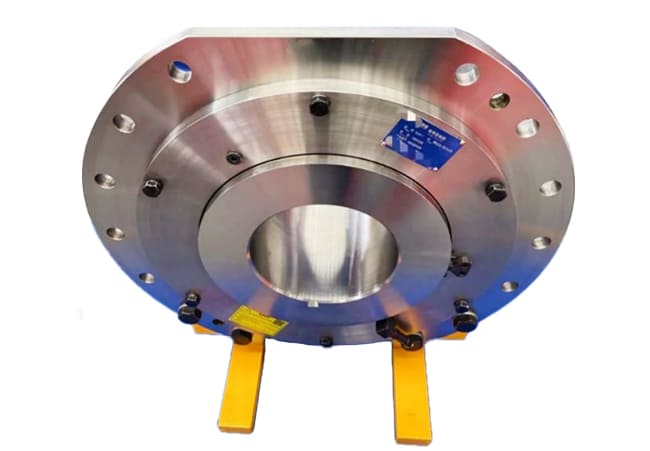

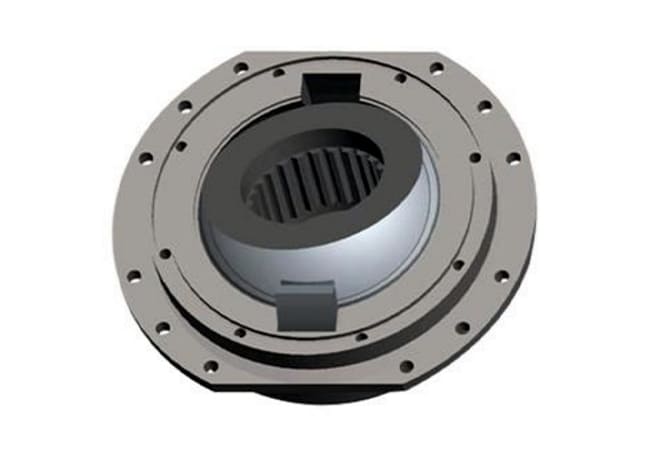

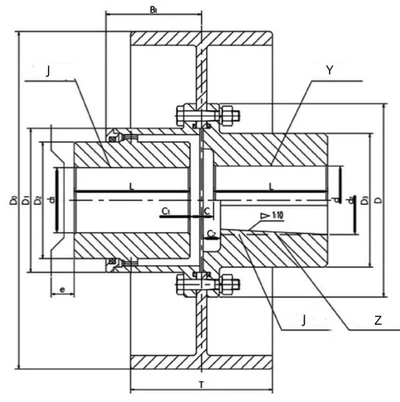

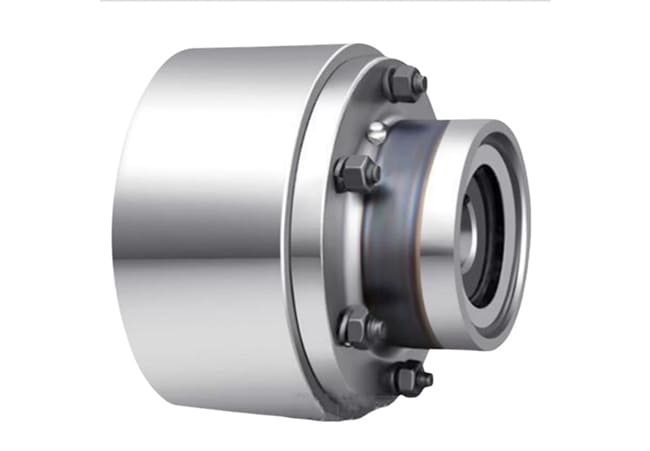

The brake wheel coupling is a vital crane part that works as a brake coupling, combining torque transfer with braking safety. Using a durable coupling with brake disc, it ensures reliable stopping, stable operation, and protection for connected equipment. Made from forged alloy steel, it offers high strength, wear resistance, and easy installation. Widely used in EOT, overhead, and gantry cranes.