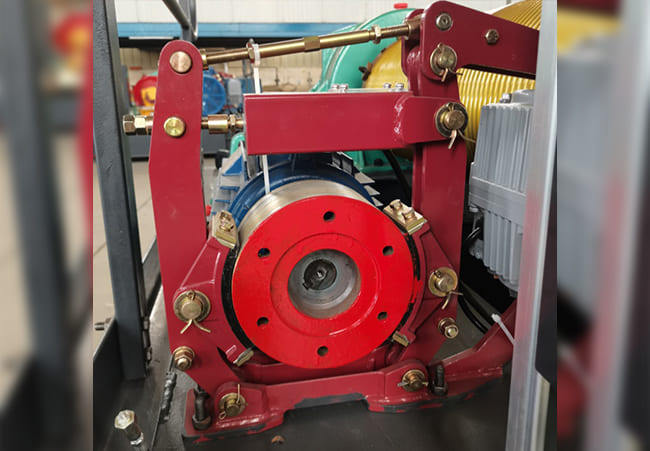

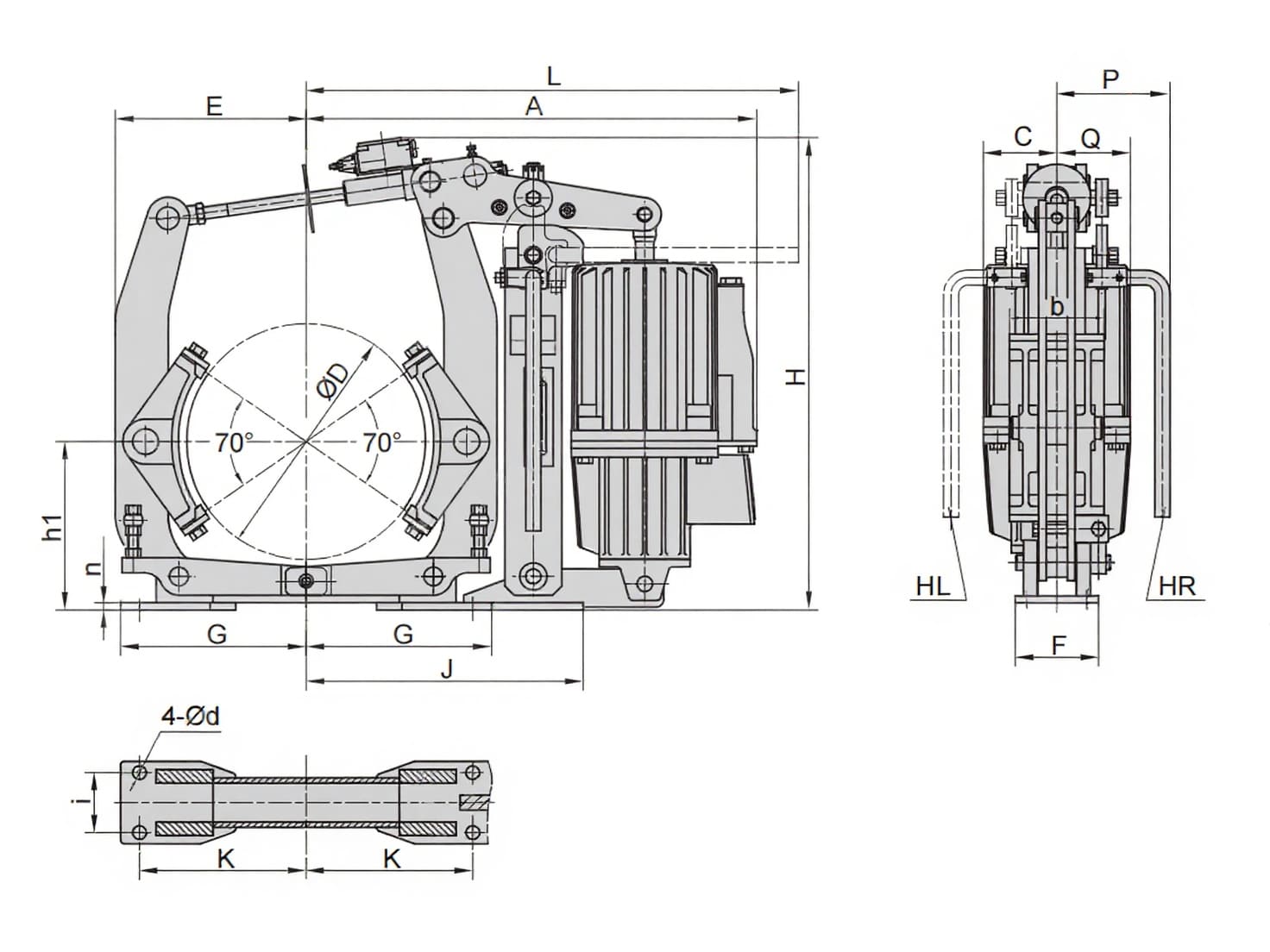

1.High Strength & Reliability: Crane drum brakes are built with premium crane brake drum material, ensuring durability under heavy loads.

2.Efficient Braking System: Overhead crane drum brake delivers smooth stopping and holding power for safe crane operations.

3.Low Maintenance Design: Precision-machined surfaces reduce wear, extending service life and lowering replacement costs.

Crane drum brakes combine strength, safety, and long-term performance, making them essential for stable lifting operations.