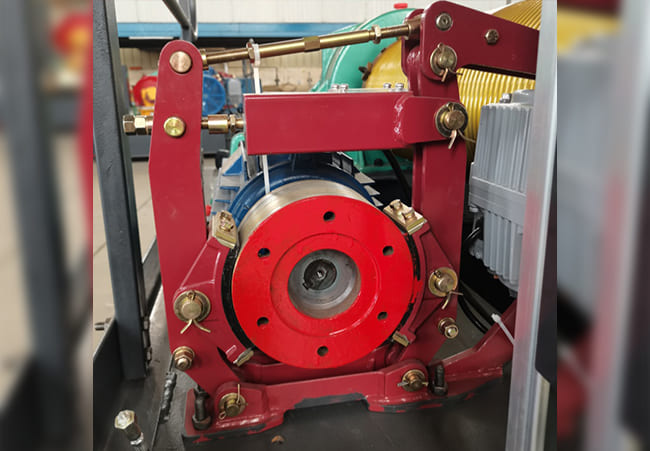

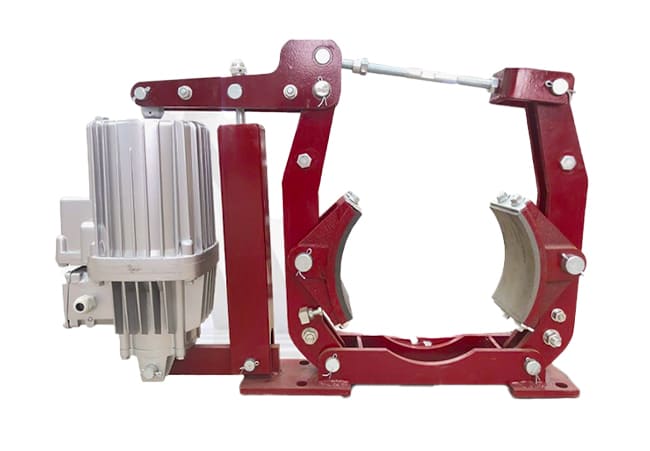

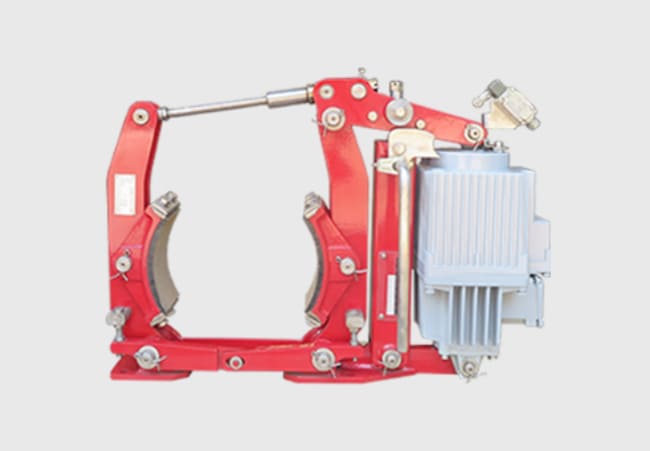

1.Reliable Stopping Power – Overhead crane brakes ensure safe load control under heavy-duty lifting conditions.

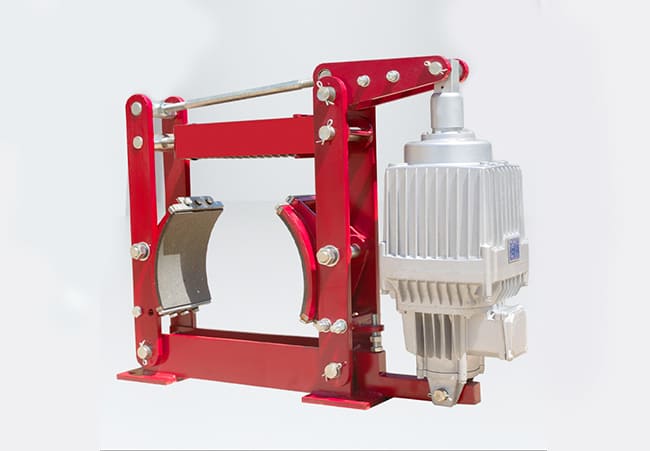

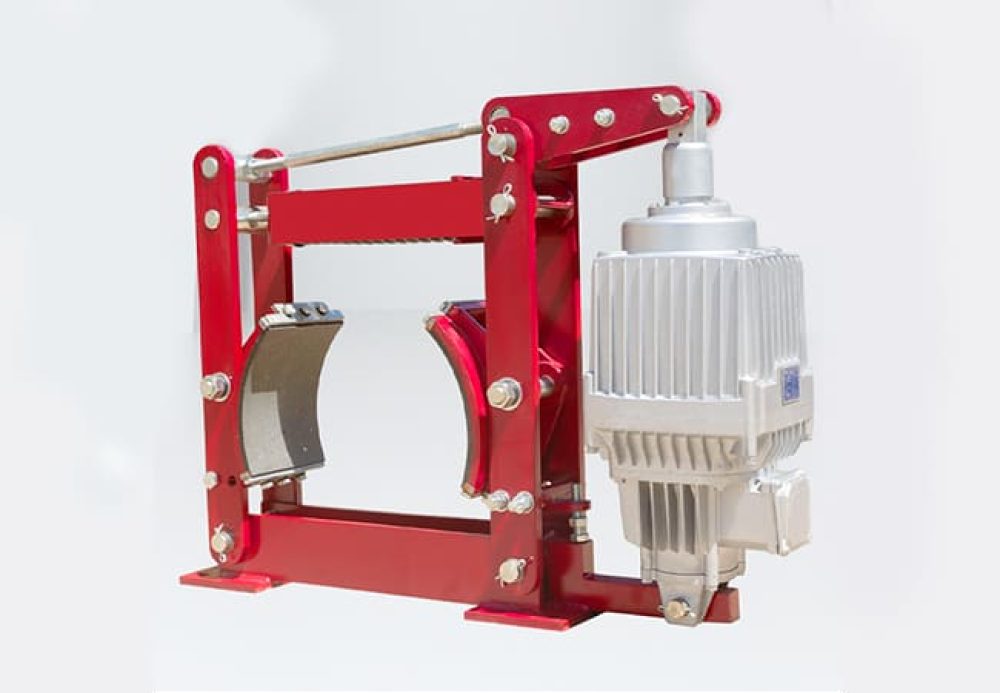

2.Durable Materials – Made from alloy steel and heat-treated parts for long-lasting wear resistance.

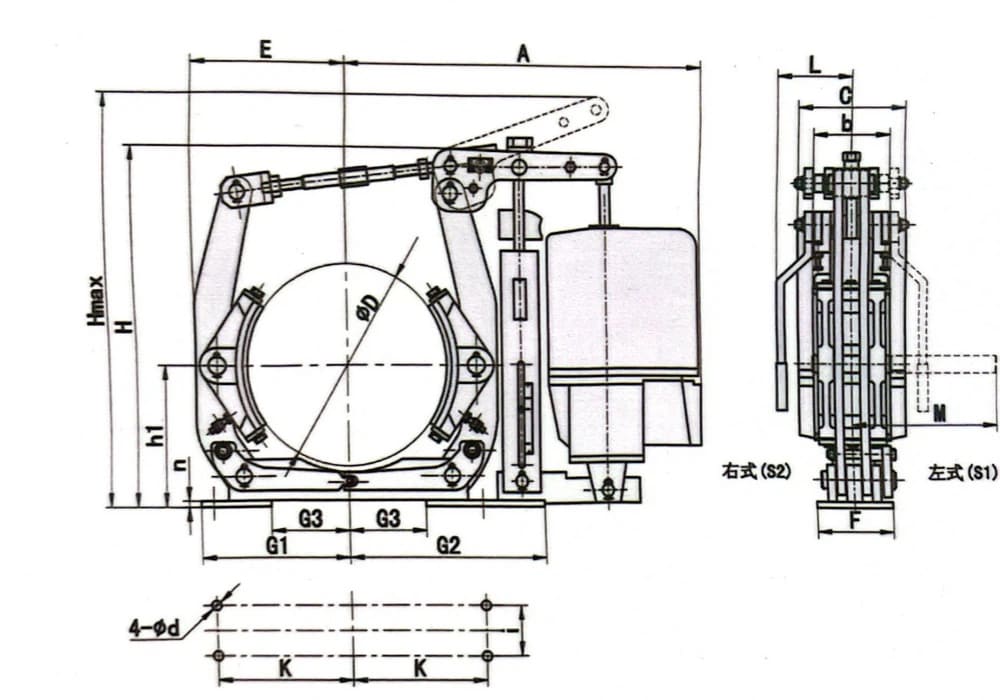

3.Efficient Design – Easy installation and low-maintenance structure fit all major crane hoist brake system types.

Overhead crane brakes provide safety, precision, and durability. They are designed to deliver smooth braking and reliable performance for continuous industrial operations.