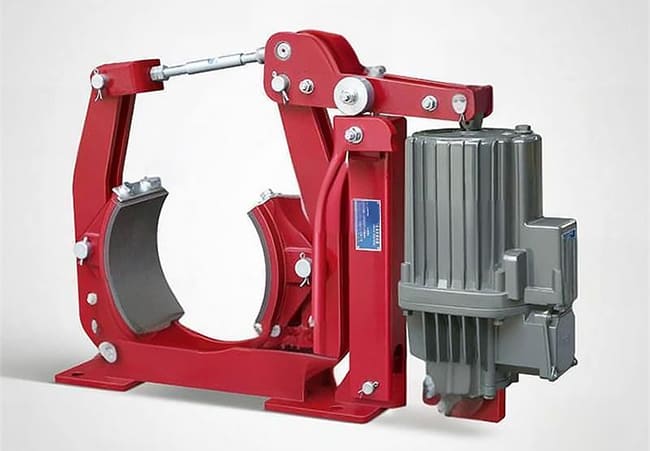

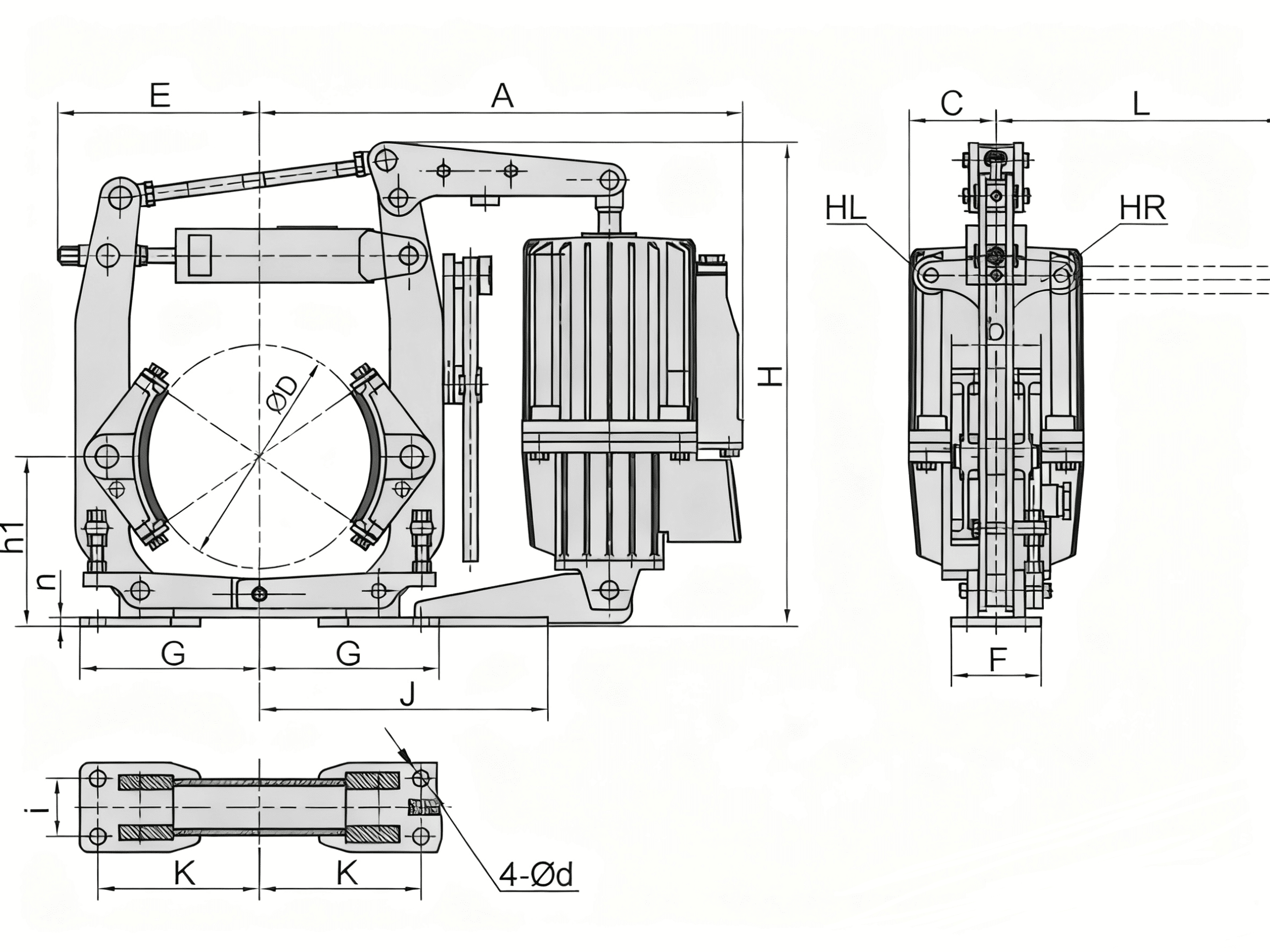

The crane hoist brake is a key safety component that ensures stable lifting and precise load control in every operation. It combines high braking torque, fast response, and reliable performance, even under heavy-duty working conditions. Designed for overhead crane brake mechanisms and EOT crane hoist brakes, it prevents accidental load drops and guarantees safe stopping. The compact design and advanced materials make the crane hoist brake system durable, low-maintenance, and adaptable to various industrial cranes.