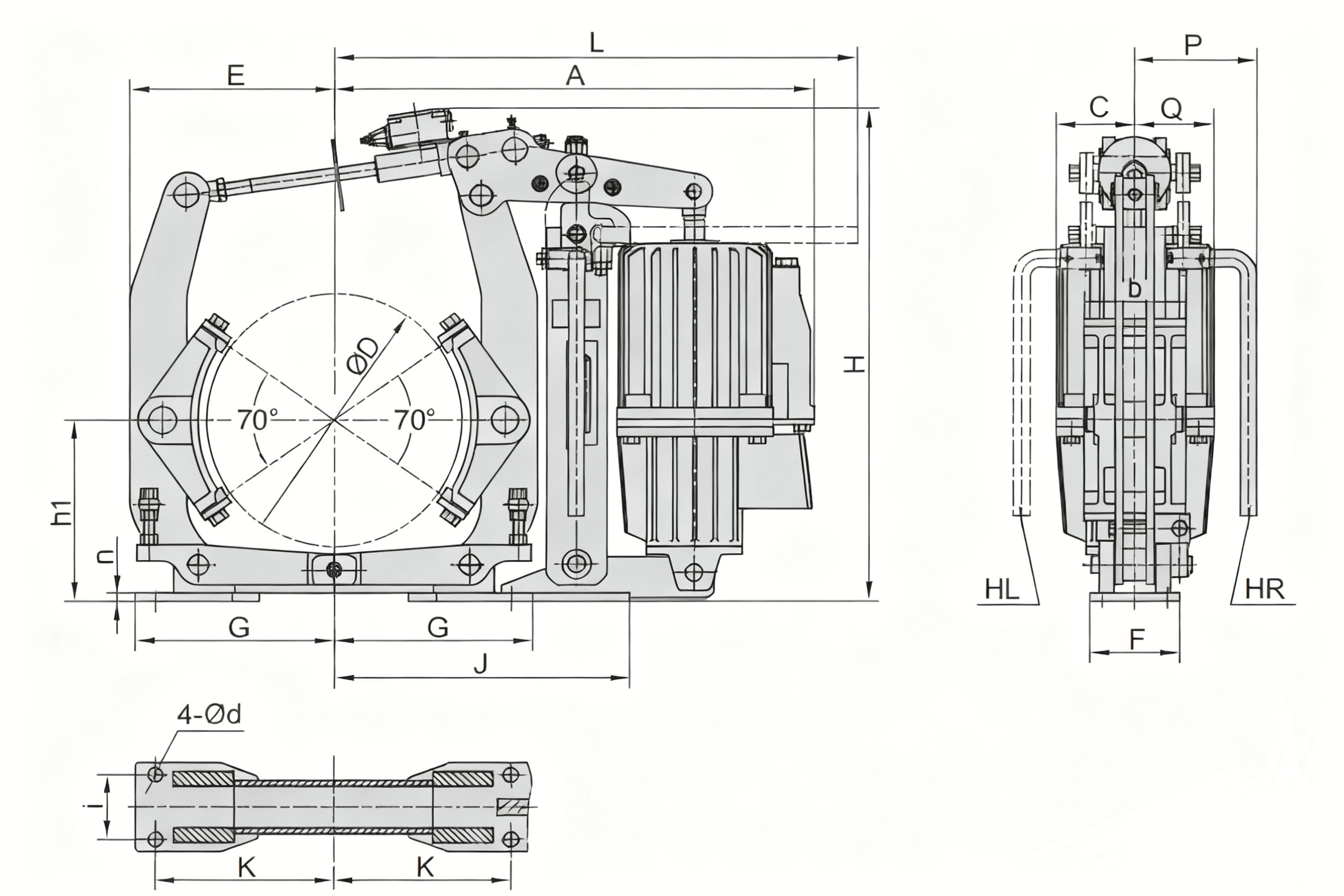

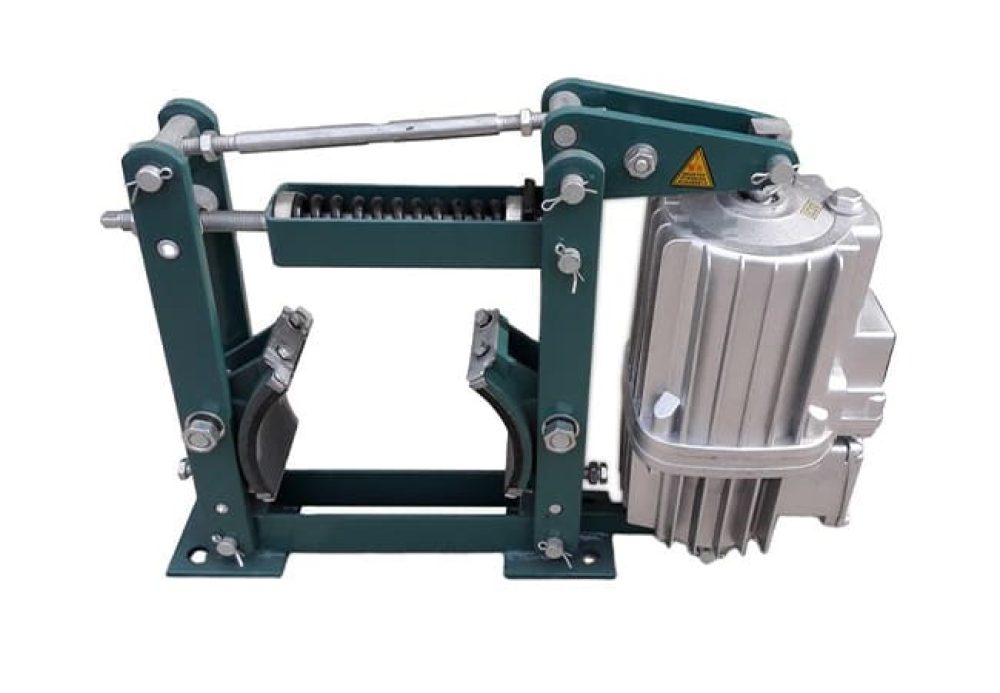

The gantry crane brakes are designed for precise load control, reliable stopping, and maximum safety in heavy-duty lifting operations. Built with advanced friction materials and precise machining, the system ensures consistent performance under high loads and frequent start-stop cycles. Each gantry crane brake assembly provides fast response, stable braking torque, and easy gantry crane brake adjustment, reducing downtime and maintenance costs. Suitable for overhead crane brakes, bridge crane brakes, and other industrial cranes, these brakes ensure smooth operation and long service life in ports, workshops, and steel plants.