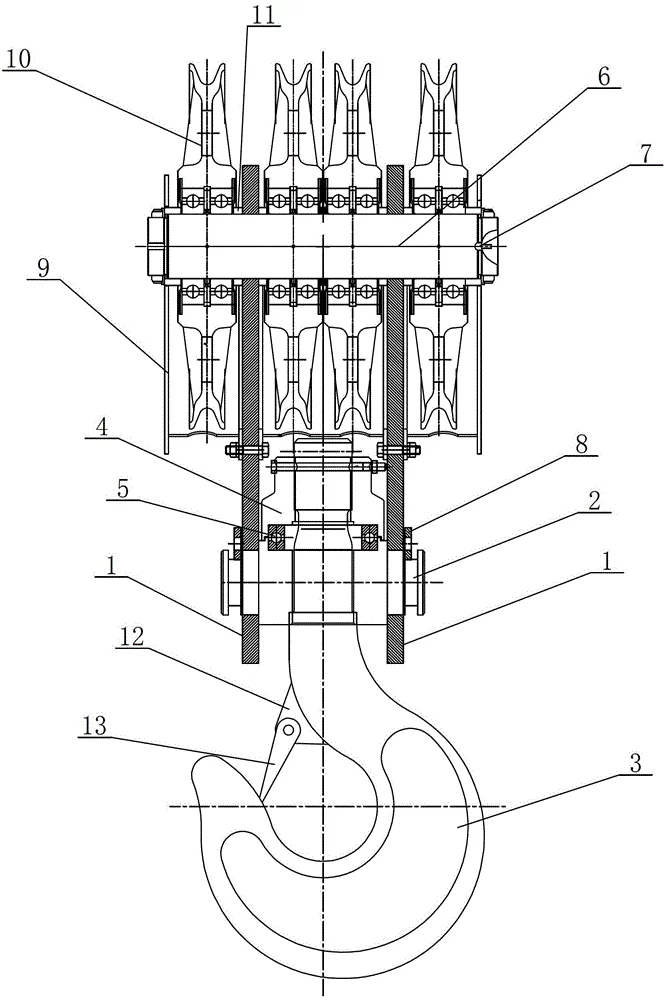

1.Super Load Capacity: The crane main hook block is one-piece forged from alloy steel, tensile strength >800 MPa. With heat treatment, wear resistance is 30% higher than standard hooks.

2.Precision & Adaptability: Each hook block crane is CNC-machined with self-lubricating bushings, lowering noise (≤65 dB). Fits over 90% of crane brands.

3.Strict Safety Testing: Every main hook block passes magnetic inspection, ultrasonic checks, and 1.5× load testing.

4.Flexible Customization: Options include hook size, pulley number, and lifting points. We provide fast service, 1-year warranty, and lifelong support.