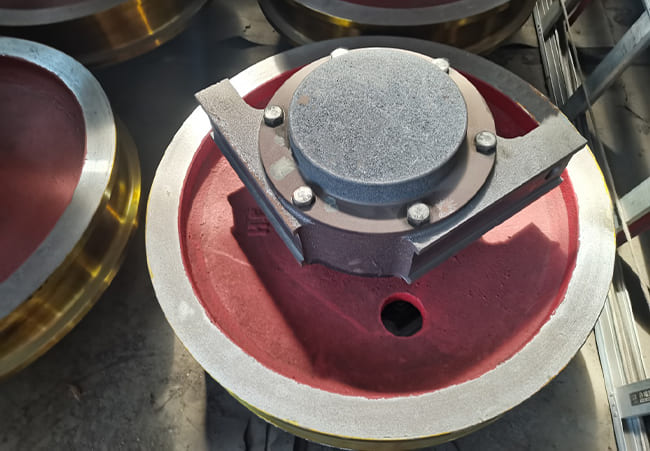

1.High Load Capacity – Bridge Crane Drive Wheels are made from high-strength forged or cast steel, capable of handling heavy-duty crane operations.

2.Wear Resistance – Quenched tread (HRC40–48) provides excellent wear resistance, reducing replacement needs and extending service life.

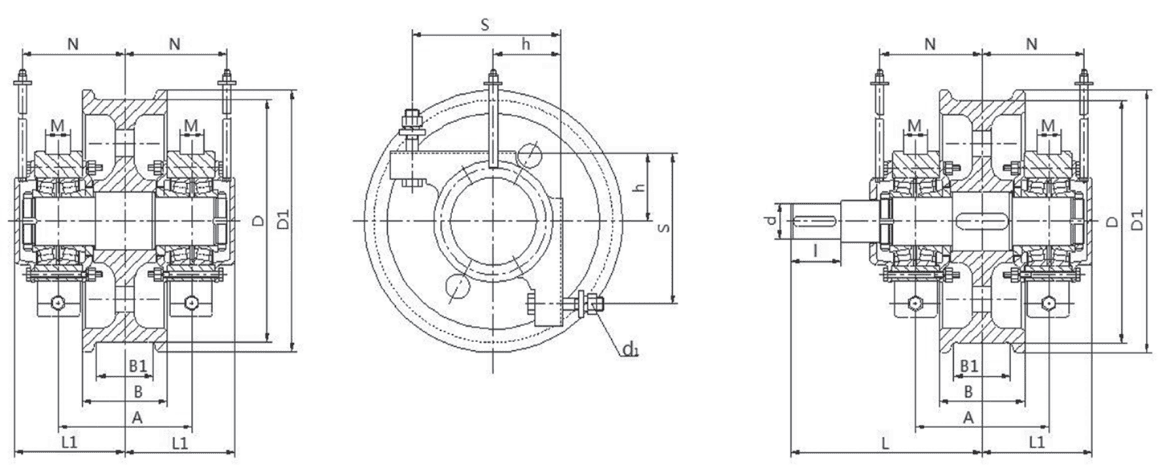

3.Easy Maintenance – Designed with angular or round bearing housings, the wheels ensure quick replacement and stable installation.

Bridge Crane Drive Wheels combine durability, stability, and safety. They are critical for smooth crane travel and reliable performance in demanding industrial environments.