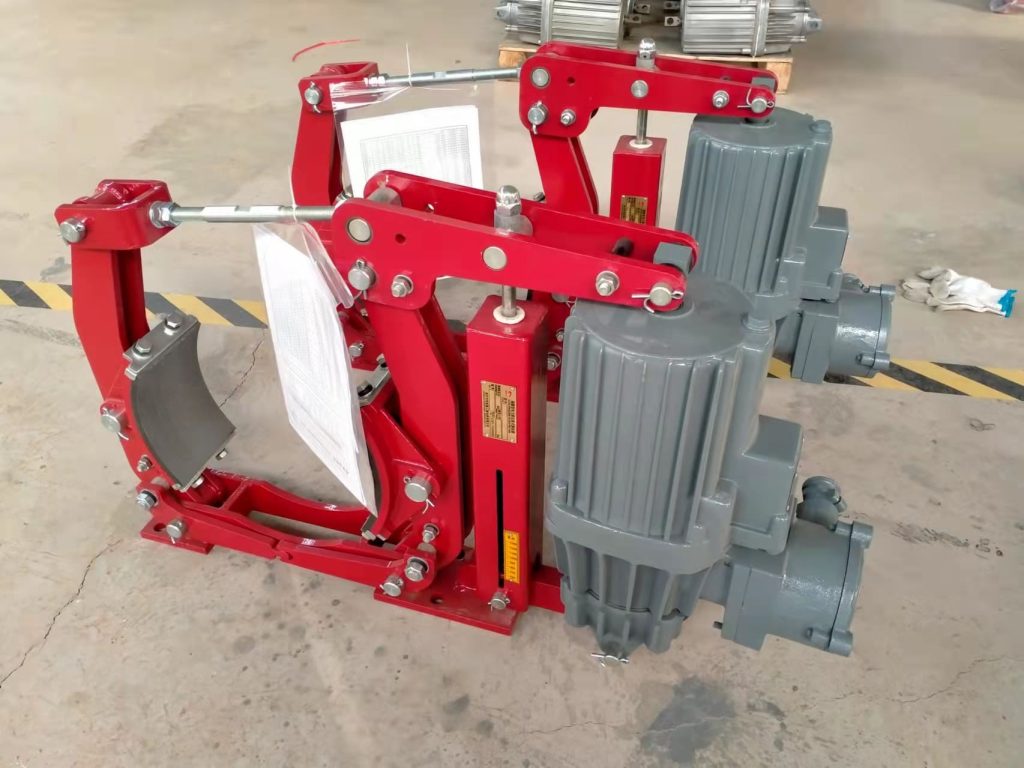

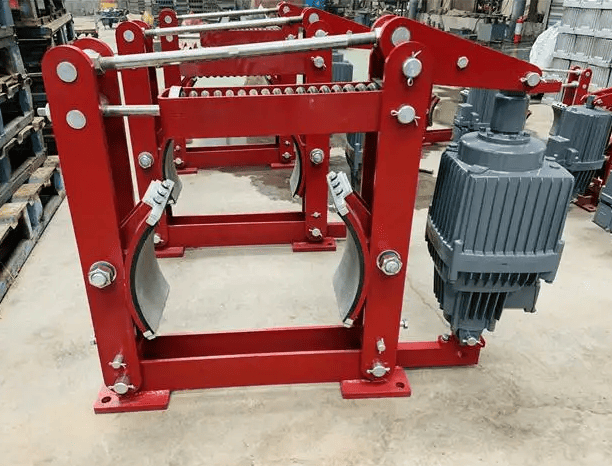

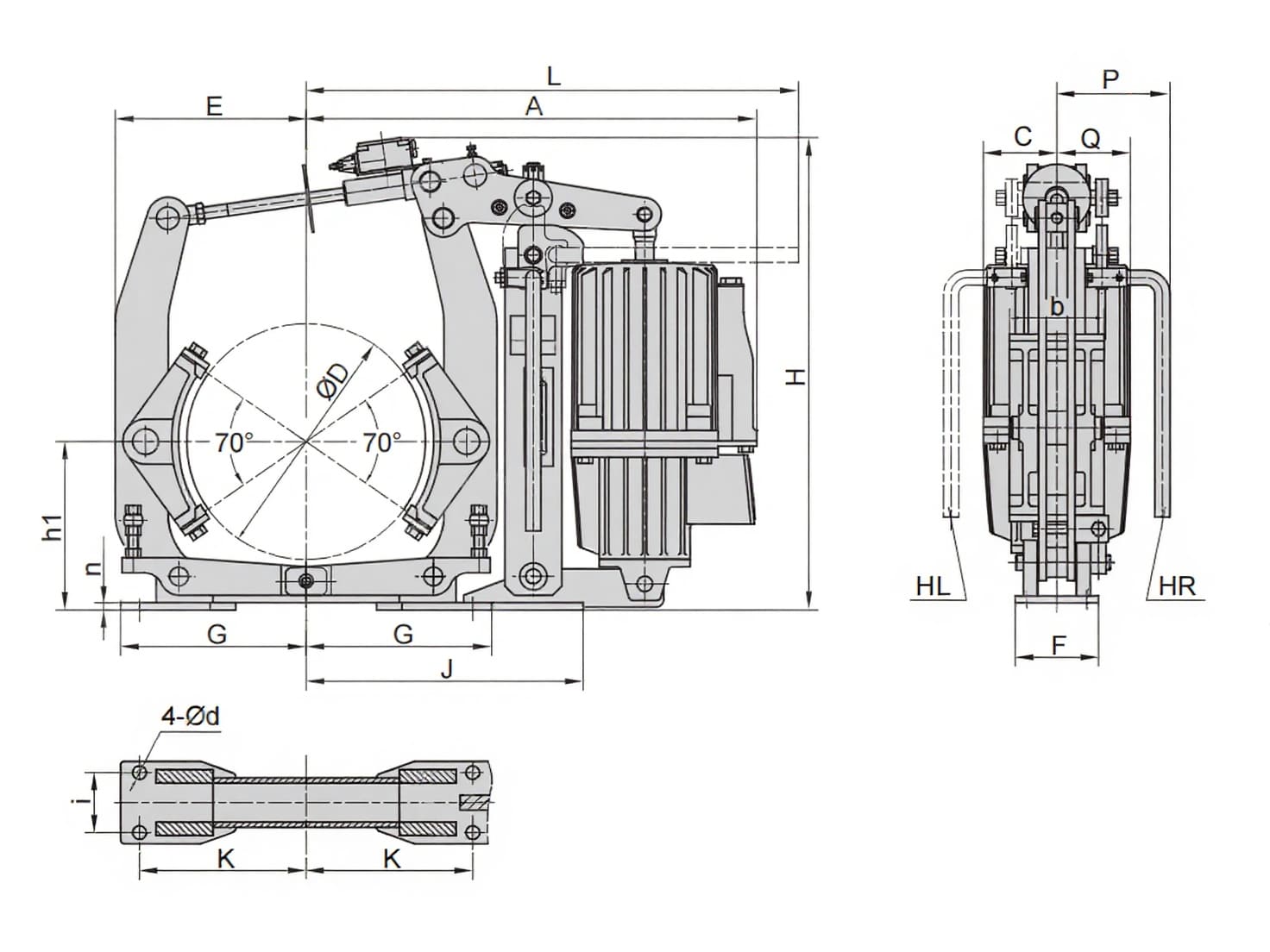

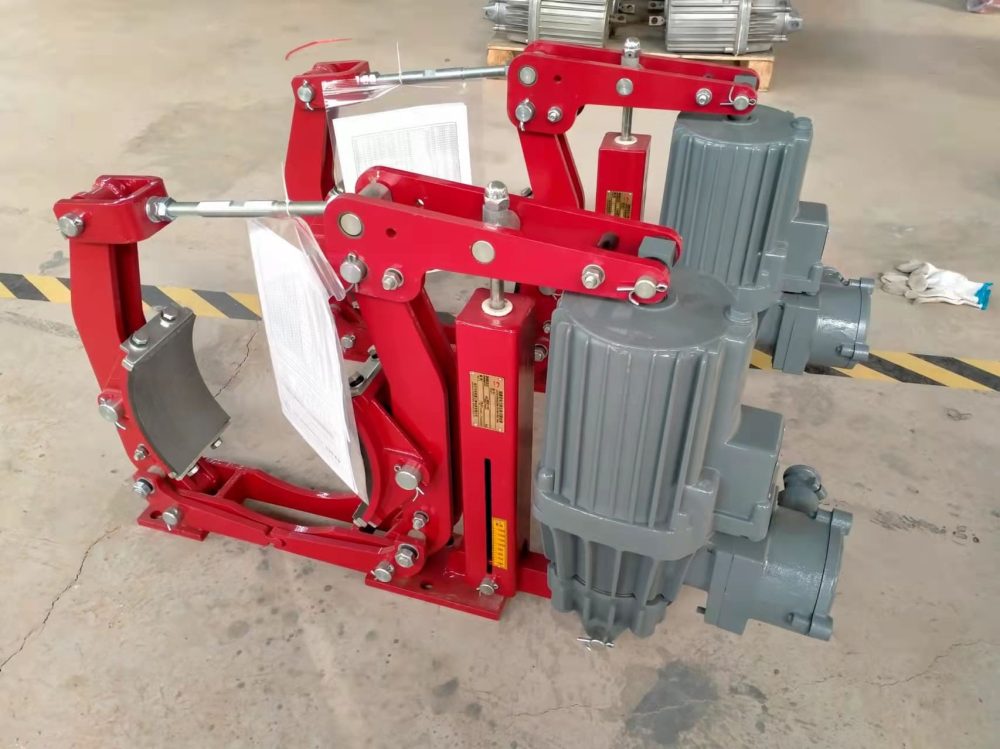

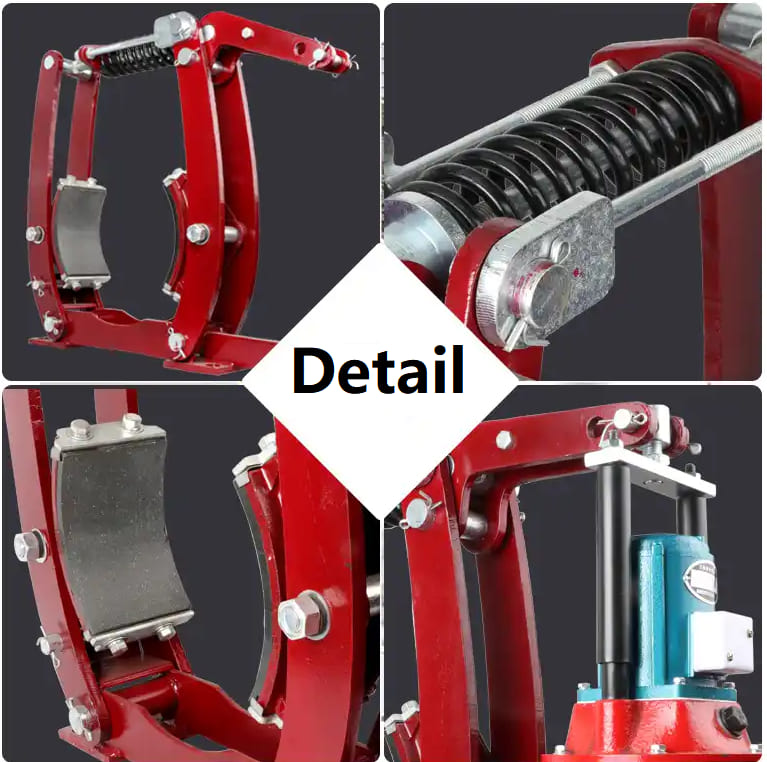

The crane brake system is a core safety component that ensures stable stopping and load control. Made with forged alloy steel and advanced friction materials, it delivers reliable performance in heavy-duty lifting. Whether used in an overhead crane brake system, EOT crane brake system, tower crane brake system, gantry crane brake system, or mobile crane brake system, it prevents accidents, reduces wear, and extends crane service life.