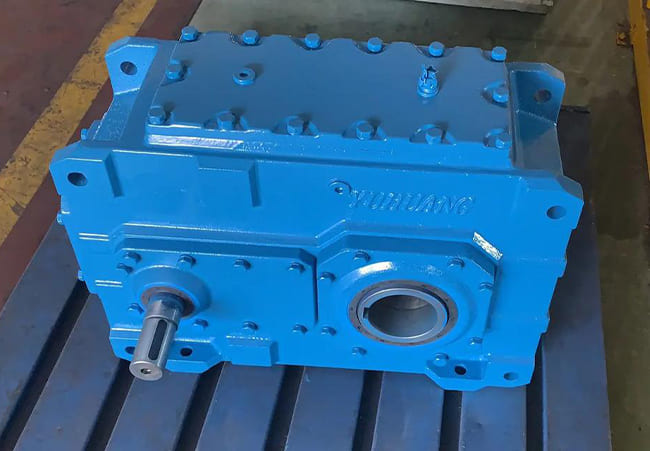

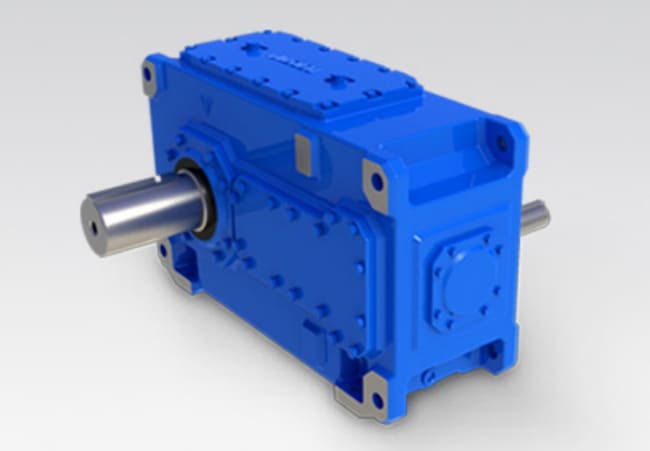

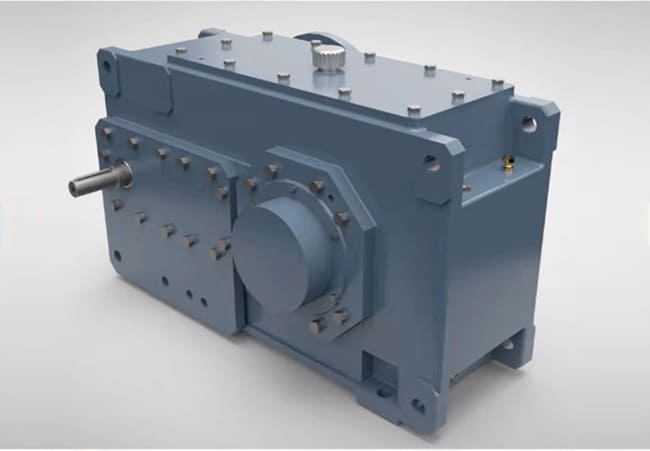

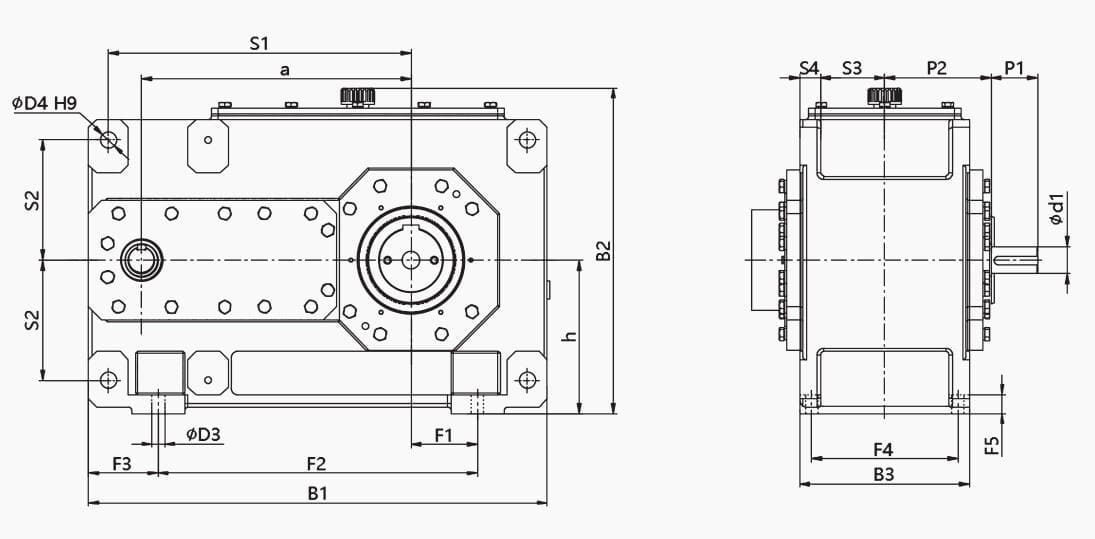

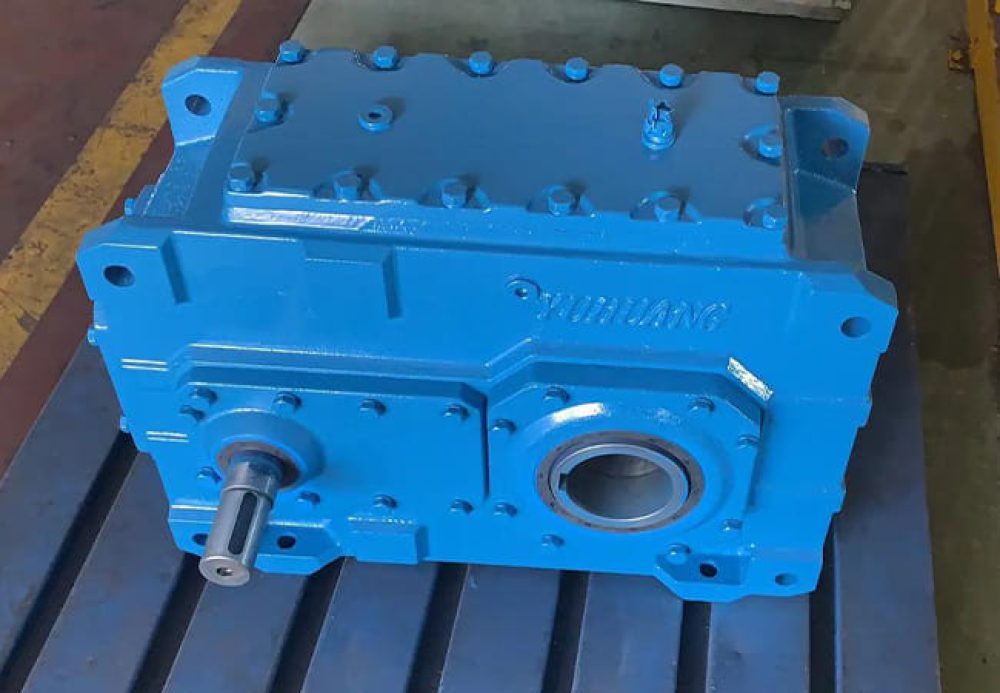

The crane hoist gearbox is the core transmission unit for lifting systems. It converts motor speed into torque, ensuring smooth and safe operations. Whether applied as an EOT crane hoist gearbox, an overhead crane hoist gearbox, or a gearbox hoist tower crane, it delivers stable performance under heavy loads. Made from alloy steel with precision ground gears, it resists wear and reduces noise. For demanding jobs, the crane main hoist gearbox and EOT crane main hoist gearbox provide reliable torque support and long service life.