1.High Load Endurance: Crane rail wheels are designed to handle heavy-duty operations with exceptional strength.

2.Superior Wear Resistance: Quenched tread surface (HRC40–48) ensures long service life with fewer replacements.

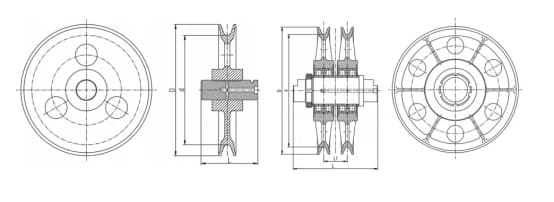

3.Stable Performance: Precision design and strong housings guarantee smooth travel and reliable safety.

Crane rail wheels combine durability, stability, and efficiency, making them essential crane wheels for heavy-duty industrial operations across various crane rail types and systems.