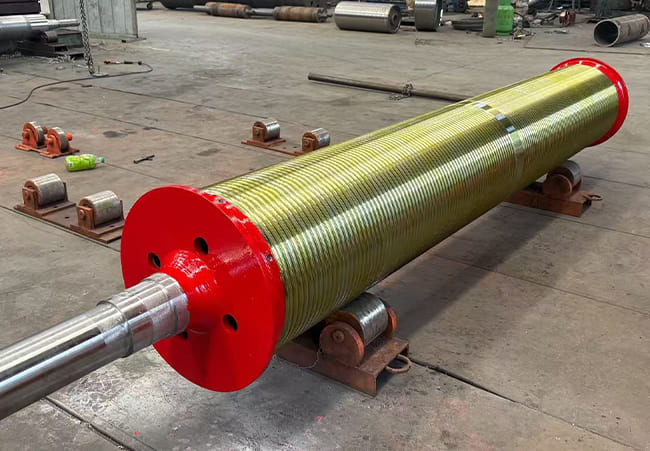

1.High Strength and Durability – Each crane rope drum is made of forged or welded steel with high load-bearing capacity.

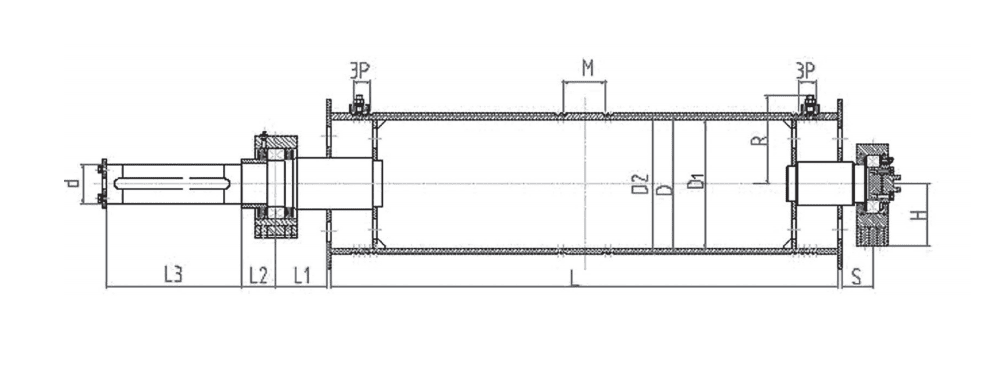

2.Accurate Groove Design – The wire rope drum groove design ensures even rope winding, reducing wear and preventing slippage.

3.Long Service Life – Heat-treated surfaces improve hardness and stability, extending the lifespan of the crane wire rope drum.

The crane rope drum combines durability, precision, and safety. It ensures smooth lifting, efficient rope management, and long-term performance in heavy-duty crane operations.