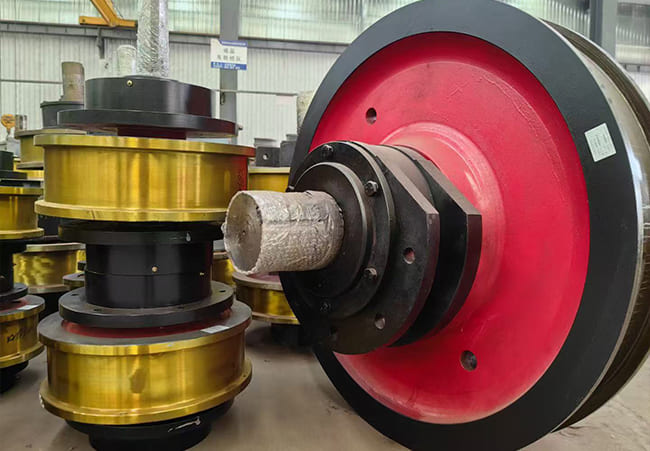

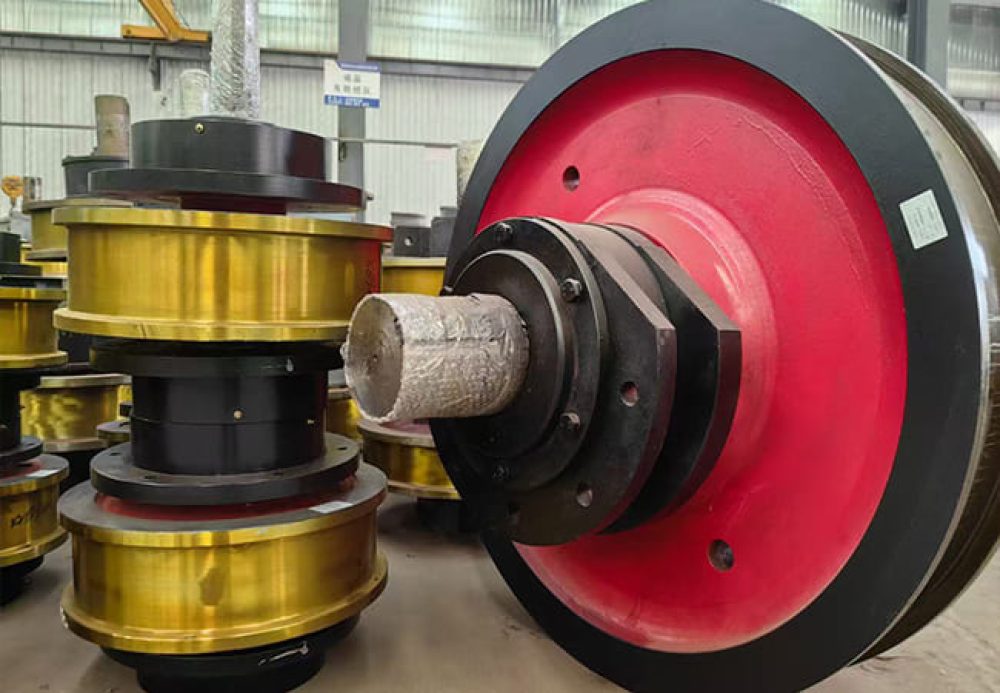

1.Made from forged or alloy steel, Crane Trolley Wheels deliver exceptional strength and wear resistance.

2.Quenched tread surface (HRC40–48) with a deep hardening layer ensures extended service life.

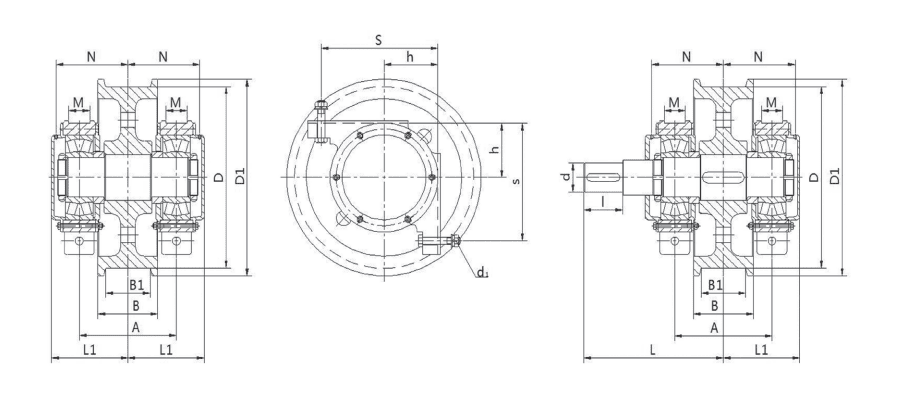

3.Precision-engineered bearing housings simplify installation, improve stability, and reduce maintenance.

Crane Trolley Wheels are critical crane wheels that support the crane’s weight and ensure smooth, stable travel. Built with premium materials and advanced heat treatment, these wheels offer high load-bearing capacity, resistance to wear, and reliable operation. Suitable for standard and customized crane wheel assembly, they enhance efficiency and minimize downtime.