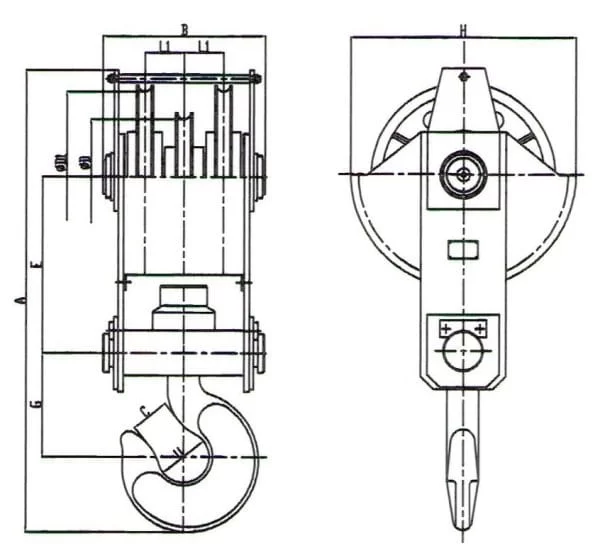

The eot crane hook is a vital lifting part for EOT cranes, designed for both main hook crane and crane auxiliary hook applications. Forged from high-strength alloy steel, it delivers outstanding durability and load capacity. Each hook is equipped with an eot crane hook latch or optional eot crane hook safety latch to prevent slipping. With robust structure and flexible use, it is trusted in construction, ports, metallurgy, and shipbuilding.