1.High Strength & Durability – Made from forged alloy steel with quenching treatment for superior load capacity and wear resistance.

2.Precision Engineering – Accurate machining ensures smooth rail contact, reducing vibration and extending service life.

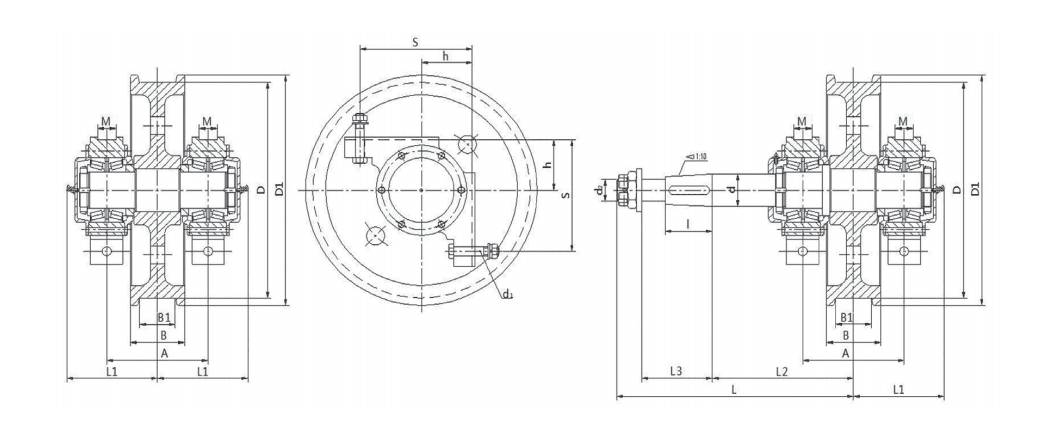

3.Easy Maintenance – Modular design with angular and round bearing housings allows fast replacement and reliable operation.

EOT crane wheels are designed to support heavy-duty operations with excellent strength, wear resistance, and stability. Manufactured with advanced heat treatment and precision machining, they ensure smooth performance and long service life. Easy to install and maintain, they are ideal for various lifting applications in demanding industrial environments.