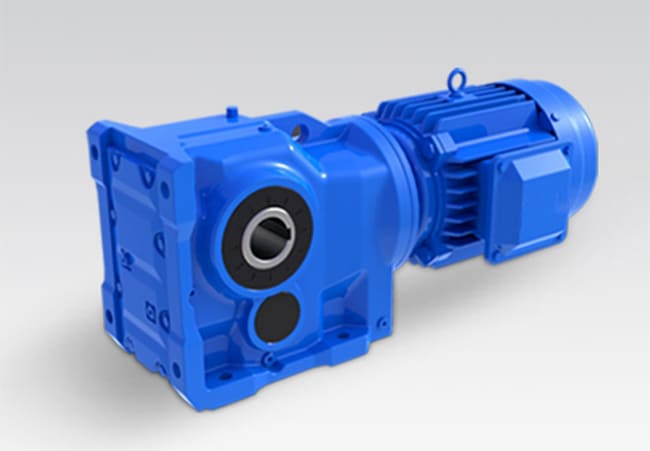

The gantry crane gearbox powers lifting by reducing motor speed and increasing torque. Built from high-strength alloy steel, the gantry crane gearbox resists wear, handles frequent start-stop cycles, and performs reliably in ports, factories, shipyards, and construction sites. Its compact design saves space, while flexible installation ensures compatibility with different crane models. With stable power transfer and customized options, the gantry crane gearbox delivers efficiency, durability, and long service life.