1.High Load Capacity: Forged from high-strength alloy steel, Gantry Crane Wheels ensure stable performance in the most demanding lifting operations.

2.Wear-Resistant & Long Lifespan: Quenched tread hardness HRC40–48 extends service life and minimizes replacement frequency for heavy duty wheels for gantry crane applications.

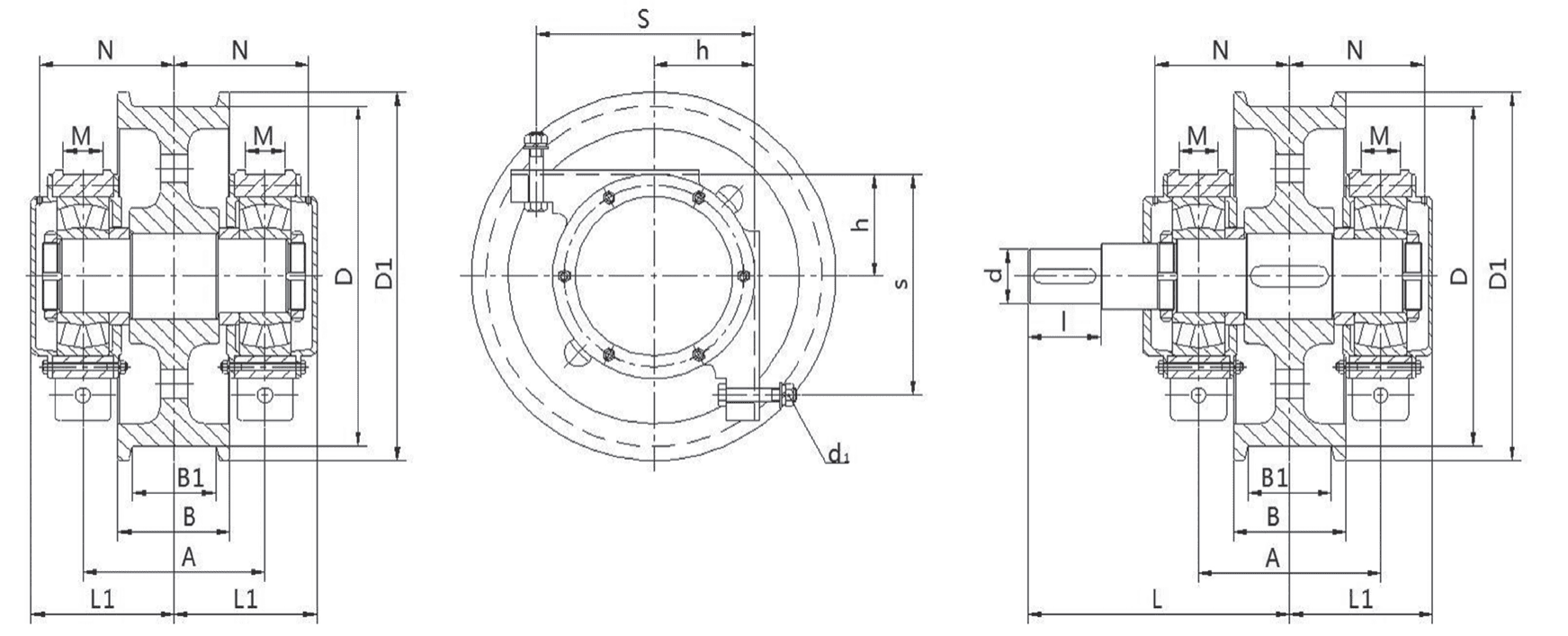

3.Easy Maintenance Design: Equipped with angular and round bearing housings, our wheels simplify maintenance for gantry crane trolley wheels and other systems.

Our gantry crane wheels for sale are engineered for durability and precision, making them ideal for heavy-duty gantry crane operations, ensuring long-term reliability and safety.