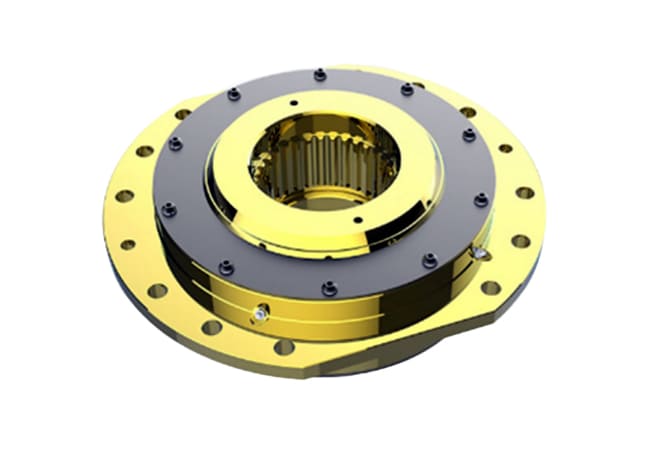

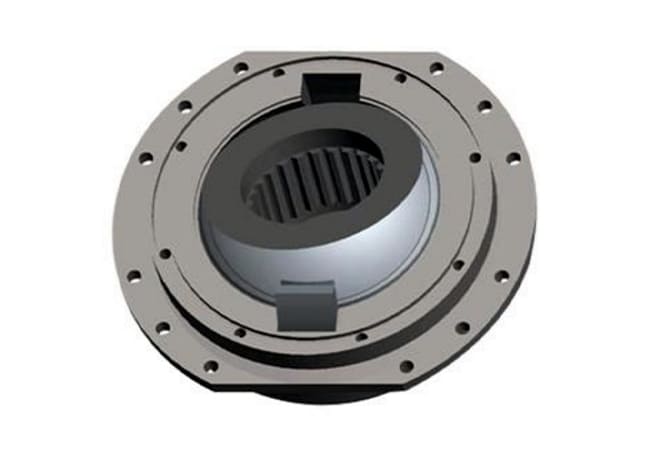

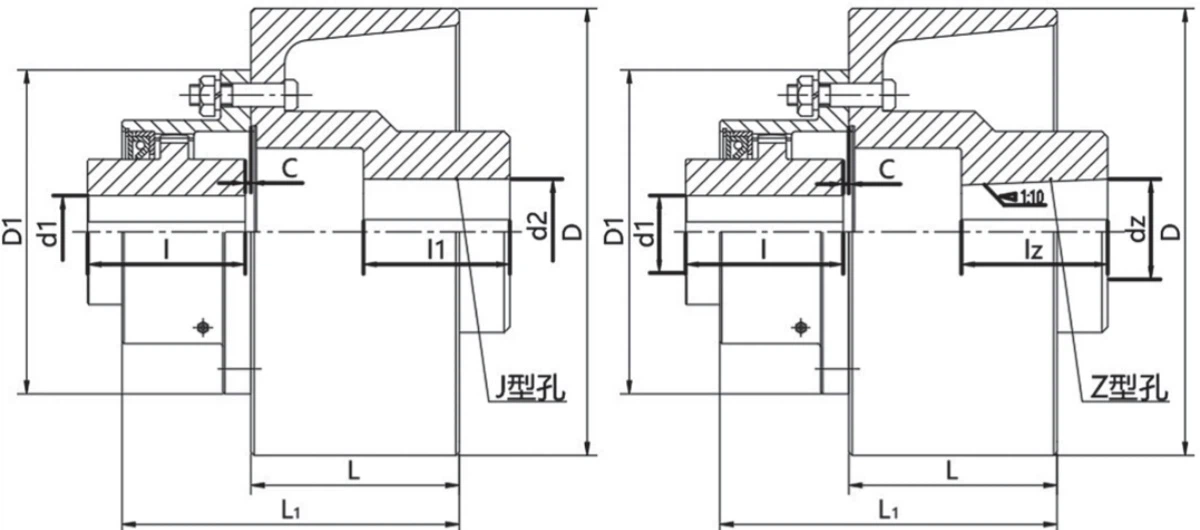

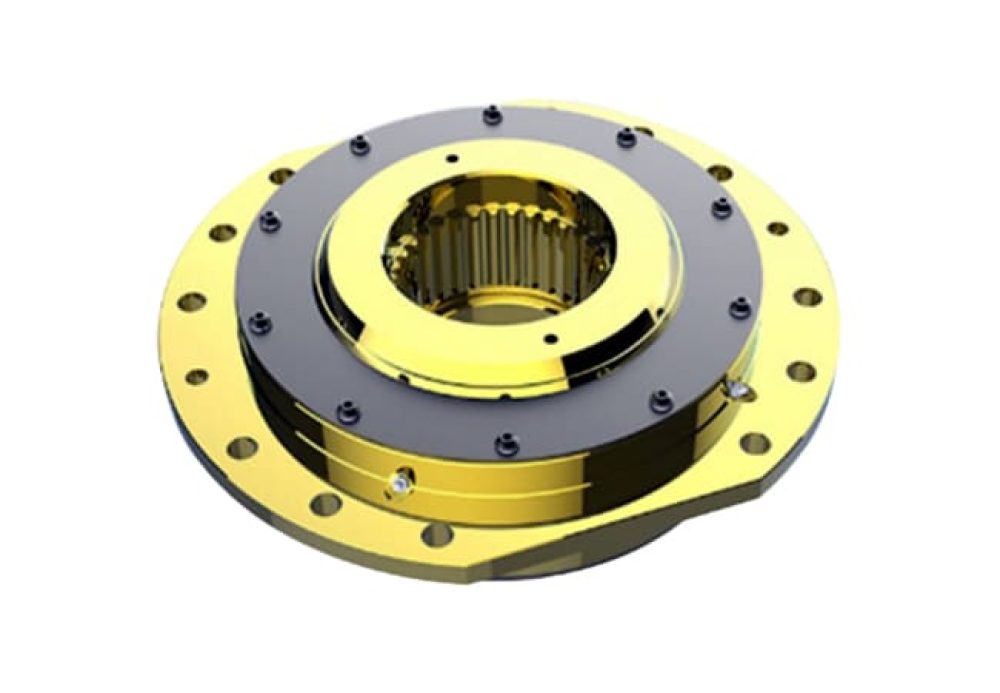

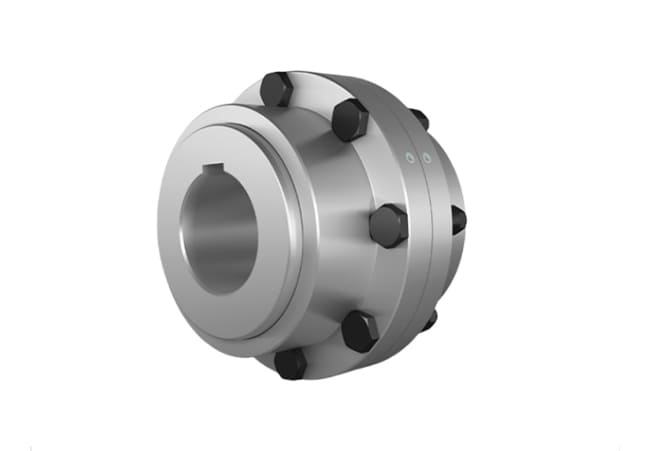

Gear couplings are precision-engineered mechanical devices that transmit torque between two shafts while compensating for misalignment. They provide high torque capacity, durability, and smooth power transmission. With compact design and strong gear teeth engagement, gear couplings reduce vibration and protect connected equipment. They are widely used in cranes, heavy machinery, and industrial drives. Simple maintenance and long service life make them a cost-effective choice.