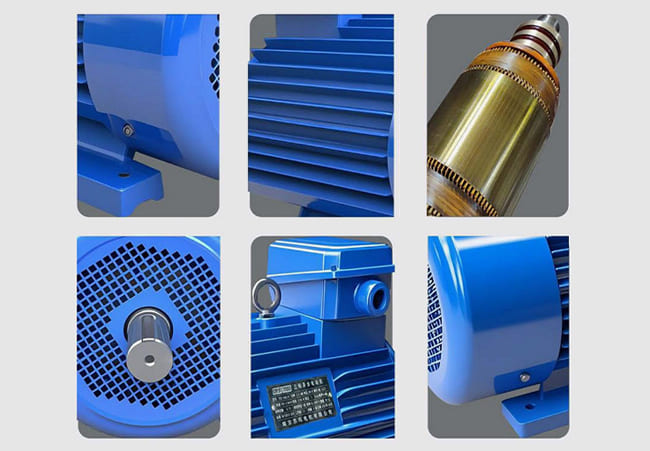

1.High Torque Output: Specially designed hoist motor core delivers stable lifting for 1–50 ton cranes with fast response and no jitter.

2.Durability: Alloy housing with anti-corrosion treatment adapts to humid and dusty sites.

3.Safety Assurance: Integrated hoist motor brake, overload and overheating protection, with instant stop when abnormal signals occur.

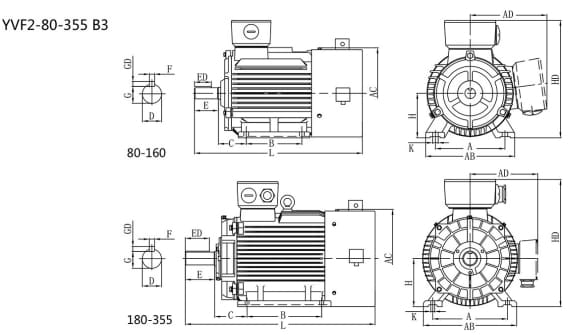

4.Easy Installation & Maintenance: Compact size, standardized mounting dimensions, and simple disassembly of key parts.

5.Compatibility: Fits mainstream crane hoist motor type designs without modification.