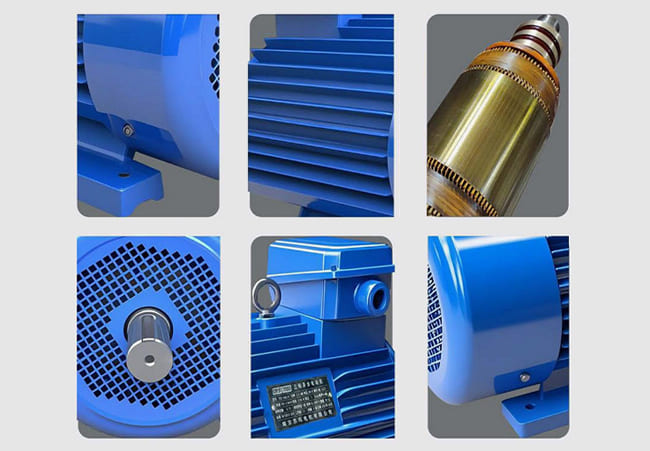

The motor for hoist crane is designed for heavy-duty lifting with stable torque, quick response, and high impact resistance. It endures frequent start-stop cycles and overload shocks, making it ideal for bridge cranes, gantry cranes, and tower cranes. With anti-corrosion housing and moisture-resistant insulation, this hoist motor for crane performs reliably in workshops and outdoor sites. Compact and easy to install, it reduces maintenance costs while ensuring efficiency and safety across industries.