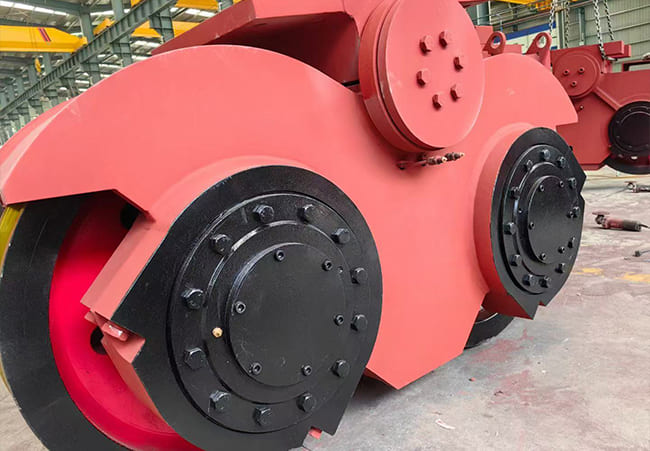

Our steel crane wheels are crafted from high-strength forged steel, designed for durability and superior load capacity. Ideal for various crane systems, including overhead cranes, gantry cranes, and crane drive wheels, these wheels reduce wear and ensure smooth movement. Available in a range of crane wheel dimensions and crane wheel specifications, they provide long-lasting performance for heavy-duty applications. Whether you need crane wheels suppliers or crane wheel price, we offer customized solutions to meet your needs.